Before this one made it to the garage from a trip to Baden in a borrowed minivan, there were obvious differences. The cabinet had been painted, coated in a flat blue-black and then sprinkled with specks of white as if it were a chunk cut from the sky's clear night; celestial, cosmic, and seemingly random. It didn't occur to me that it wasn't by accident, that the specks might line up or that it might be a map to some lost colony. The image wasn't clear or precise, appearing as if captured in motion as the photographer had been hurled through space.

When I checked the cords... it felt like all of this has happened before. The ones to the motor and the lines to the controls were okay but this time hidden behind the the front door one wire had snapped completely in half. There had been a chance, a hidden opportunity for it to have lit up the entire deck: death by electrified VSM. I don't think it was planned... but it would have been a victory for the machines. I had to laugh about it, thinking I should be a lot more careful for what I wish for: it just might kill me.

I began the trace. New wire would be required from the front of the head through the entire length of top assembly and then down in a route parallel with the connecting rods and arm shaft to a rear access port.

It's very tight inside the light assembly; very little room. The leads off the socket were good and this time. I spliced them, twined the wires together, and then used a pair of wire nuts.

It bothers me. If the light door were to be closed most of the time then there shouldn't be any issue with the arrangement, but it isn't closed all the time.

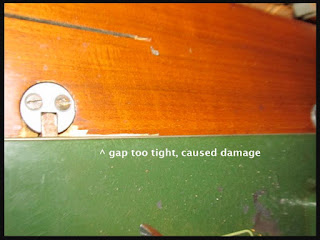

Usually, if the bulb is okay there's no reason to open it (no wiring diagram) but this model can't be raised or lowered into the cabinet cavity without opening the light door to clear the light switch. The tolerances are too tight as if the unit wasn't built for this, that it had once been re-homed.

Inside the woodwork there's a second wiring set, a disconnected knee control with wires wound in old cloth insulate. Hours passed as I replaced questionable methodologies and tried not to make more mistakes. Having it safe for the long term took precedence. The 'right now' shouldn't win over doing it right: a familiar theme in my life.

With all the wire connections secure I closed the door and re-affixed the motor then began the usual lubrication and cleaning process from the top down making sure everything was moving freely. I've included the new process of pulling the slide plate and feed dog cover to clean out all the old lint, even if I can't see it built up in between the teeth.

By the time I felt satisfied that the motor would turn all the mechs it had become dark and shadowy in the garage. Somewhere upstairs in the house someone had music playing, an eerie drifting sound.. and that's when I finally gave it power, and became concerned of what I may have awakened...

As if the star box, deja vu and broken wires hadn't been a warning...

I went over the controls. The one thing missing from the bag of extras had been an operators manual. I was going to have to guess which controls went where and cross my fingers. The one that still gets me is the top wheel. It has four settings for the internal cam. One is a zigzag, and it's polar opposite a curved stitch. On the east and west points there's a number one, and a number two and I have no clue. It might as well be hieroglyphs or the mark of an ancient alien race. I went for what I thought must be a straight setting and threaded the machine.

It complained. There was a low frequency buzzing noise and then an audible groan before the wheel turned on its own, as if it had been in hibernation too long and had to stretch and yawn. Then motion began and the wheel spun and the needle bar began a slow up and down. All of the sounds were promising, hopeful except for maybe the low vibration buzz. I pressed a little harder on the pedal. Revolutions went up and I brought them back down and it all seemed to work.

I stopped and prepared the threads and that's when I realized all the warnings were credible and found out that it's nearly impossible to set the bobbin in place without lifting the front edge. Once it was in and the machine back down, I raised the foot and asked it to pick up the lower thread by hand, and it did. I swept it back. The first stitch, straight ahead, was no problem. and since the width lever worked I began to guess at zigzag.

The setting is complicated - or maybe not, maybe I'm doing it wrong, but I set the top wheel on the zigzag icon and then turned the white front wheel to a middle setting between 1 and 6. Then I had to match that by turning the chrome knob. With those three adjustments in what I thought must be an agreement I dropped foot and tried again.

It wasn't the prettiest and there was something wrong. There was a skip in the pattern, a frakture.

By now it was well into the evening and the grill kept taunting me.

I'd see it in the corner of my eye everywhere in the garage.

Like I was being watched...

Like I was being watched...

With fatigue setting in I was certain the machine was going to beat me unless I found a harbinger;

something with historical success in winning battles against it.

The internet suggested two things:

a new needle and a Starbuck.

a new needle and a Starbuck.

I tried them both.

So I can't say which worked, but I did feel somewhat rejuvenated and after threading it all again. The zigzag came out right this time, although interesting. I've never seen one quite like this.

There was one last bit to solve. Throughout the entire process the low vibration buzz had remained. It took forever to figure it out because I couldn't feel where it was coming from. It was everywhere, a subtle but annoying noise. If I applied pressure to the deck in one corner it eased up. I added another layer of felt to the lip where the machine sits. That didn't do it. I tried tightening the pivot posts and that was the one thing that came close, so I began to adjust them in different directions. The vibration changed. Eventually through trial and error I realized there was the slightest stress against the pins. The machine was sitting at an ever-so-slight angle within the wooden frame. The angle created a tightness that reverberated the motor hum. It would have driven me insane, but it's gone now.

Maybe that's one reason why I do it. I mean sure, every time another machine comes in the door it does feel as if it's all happening again. It makes me question: if it -has to- happen all over again... and yet each time the outcome is different. The controls and this machine are different. It's smooth and interesting. Every curve and shadow in the paint seems to change hues slightly with the light. In the bright daylight it's a blue that fades toward an aqua at night. Oh, I do like this one. It makes me want to try the other two, the 840 and the Lady Kenmore 89! But I know I can't save them all. I can't even store them all. I may need to let a few more go.