The wire junction box would have to be attached to the cabinet somewhere just inside the lid - making sure there was enough wire slack for the machine to travel down and up. I needed to find a mounting screw 'just' long enough to pass through the Bakelite box and yet short enough that attaching it to the side of the cabinet did not interfere with drawer travel. I ended up using the old Singer pedal mount as a guide and after measuring the thickness of the Bakelite found a wood screw a quarter of an inch longer. The wires were indeed just long enough and the machine can travel up and down without issue. The problem was... that when the machine was lowered the hand wheel actually bumped the plugs! I had to relocate the junction box four inches back.

Then there was a search for a replacement machine pivot since one of the two original ones had broken. I got lucky in the spare parts drawer and found a matching set of pivot pins for the early Necchi mounts. These pins had been in the BU head when it first arrived and were replaced with a newer set that I had to grind down ever-so-slightly to fit into the machine.

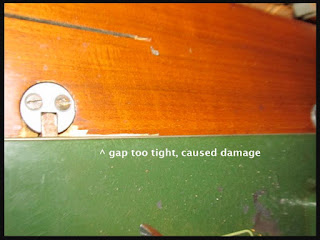

I did manage however to adjust the width of the machine on the pins so that it could pivot back and forth without causing any further damage to the veneer edge. Someday, I will have to make repairs here, but for now, it is inside, and ready to use.

*For those that don't know, the pivot pin diameter for late 40's early 50's Necchi's are smaller than most other manufacturers, and the mounting holes are drilled for that pin diameter. More modern (or more readily available pins will not fit). Either the mounting holes on the machine must be drilled out, or the new pins must be reduced slightly. I choose to reduce the pins slightly since both the BU and the Nova are forty pound machines. I'd rather have a pin snap than a machine case crack.

So here she sits, ready to go. There are two last things on the list: finding a light cover, and replacing the odd little bits on the cabinet handles. If I can find a local cabinet maker perhaps I can purchase a few bits of marble trim to sand down to size.

By the afternoon, Anne was as complete as she could be, back in her cabinet and ready to go and just in time for Jacob to arrive. Jacob was looking for a different sewing machine. He had one, but needed something durable with parts availability and hoped to find one that did a little more than straight ahead and back-tack. I was ready for him and had cleaned up and oiled the Singer 401. The machine and attachments had arrived here as a gift, and although it did need a good going over at the time, it had been here for over a year and rarely used. The photo above is how it looked on the day it arrived

After he checked it all out and realized that any and all of the attachments on the 401 would work with his Mothers 500A... we packed it up in a travel case. Sometime this week we'll arrange a time when I can go and pick up his old cabinet machine which ends up being a 15-91 in a type 40 table. It's funny though in that it still feels awkward to watch a machine leave the garage. I can remember the day and the weather, and could probably drive right over to where I picked the machine up last year.

Sunday morning became the day to tackle the broken zigzag lever on the Singer 237 from the estate sale two weeks ago. I'd spent a few fruitless hours looking around the garage for something that might fit and finally stumbled (quite literally - because I accidentally kicked the piece) upon a parts machine cover that held a couple of interesting clips. They were about the right length, about the correct thickness, and had just the one little hole on one end... and sure enough it was about as good as it could get.

The piece slipped right into where the original lever mounted! The only issue that concerns me right now is the width. It's possible that because this lever is twice the width of the old one that some fraction of stitch variance may be lost, but after testing, the machine is doing a straight stitch, and the zigzag doesn't look to shabby.

With those three machines now mostly out of the way, I sat down to check local sales on Sunday afternoon and found an unusual image. It had that deja-vu feeling to it, very much like the experience with the Nova. There was 'something' to it that I knew... even though there wasn't really enough of a photo to clearly identify the machine. Before I even tried to hunt down an identification, I responded to the ad and crossed my fingers that I wasn't too late, which was good on my part because now, today, Monday, I'm supposed to pick it up at 3:30.

Here are the two photos from the CL listing:

It makes me wonder if anyone else can do it, or is it just me? I've been looking for one of these, waiting for it to happen. If it is indeed what I think it is... then my sewing basket list of machines to find and experience has been significantly reduced. It may be that I only have the Pfaff 130 and perhaps a Mira left.

There's still plenty to do here, and more machines to find a home, but I really need to start setting new goals. I'm running out of old ones! Now I have not yet gone to get the machine above, and perhaps I'm wrong... but it really does -appear- to be a 1956 Kenmore 117.740. This would be the German made machine and if it's been in a damp place for a very long time, it may be difficult to get running again. Tolerances were very tight on the machines made by Gritzner

I guess we'll wait and see...

*just got home and figured out how to lift the machine up (have to open the light door). and here it is:

The 1956 Kenmore 117.740 - imported by White - manufactured by Gritzer-Kayser zig zag machine!

No comments:

Post a Comment